We extend a warm welcome to FGC Contracting LLC, where we are dedicated to enhancing and improving your infrastructure projects through our efficient and innovative technological solutions. We specialize in Horizontal Directional Drilling (HDD) services, meticulously designed to meet the diverse needs of contemporary businesses and construction endeavors, while also providing cost-effective and efficient underground utility installations.

Therefore, if you require the laying of pipes, cables, or conduits, whether above or below ground, our team of Horizontal Directional Drilling experts is committed to ensuring your project is executed with the utmost quality and care.

We are a leading provider of Horizontal Directional Drilling (HDD) services company, offering innovative and cost-effective solutions in Abu Dhabi, Dubai, Sharjah, Ajman, Umm Al Quwain, Ras Al Khaimah, Fujairah and all UAE regions.

What is Horizontal Directional Drilling (HDD)?

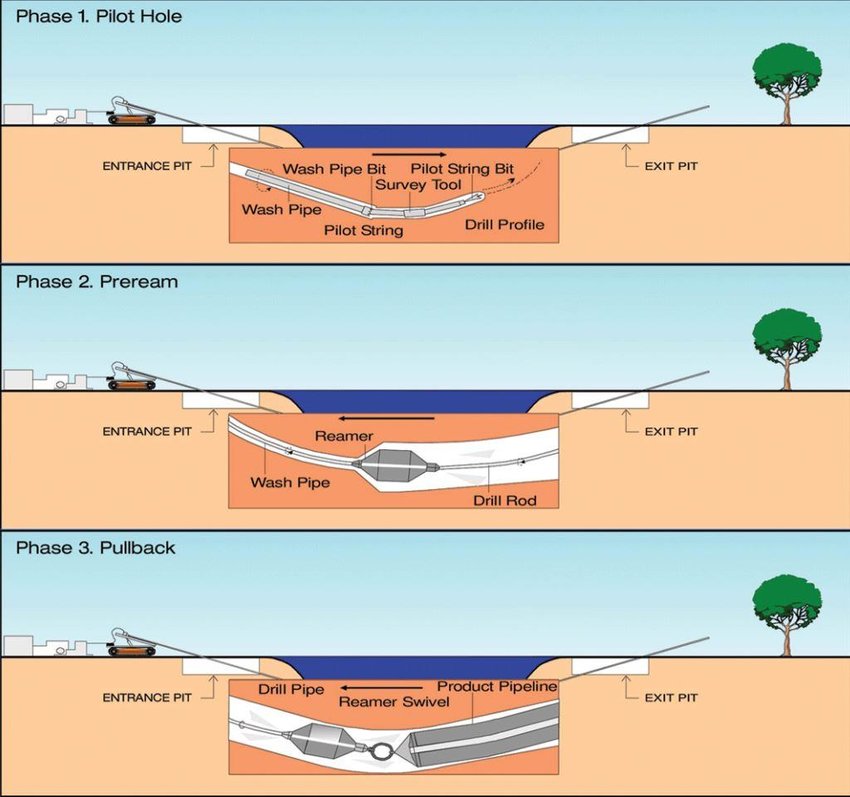

Horizontal Directional Drilling (HDD) is a trenchless drilling technique employed for the installation of subterranean pipelines and cables. HDD facilitates the placement of these utilities without the necessity for extensive excavation, thereby distinguishing it from conventional drilling methods. The process involves the creation of a pilot bore along a predetermined trajectory, which is subsequently enlarged to accommodate the specifications of the pipelines. Following this, the pipelines are drawn through the borehole, thereby enabling the installation of the system with minimal surface disturbance.

We are a leading provider of Horizontal Directional Drilling (HDD) services, offering innovative and cost-effective solutions for a wide range of infrastructure and utility projects. Whether you’re installing pipelines, cables, or other utilities, our advanced techniques ensure minimal disruption to the environment and the surrounding area.

Horizontal directional drilling company (HDD) is a surface-to-surface installation technique used to install pipelines in areas not amenable to open-cut construction. HDD is a pipe installation technique used to install pipes in busy areas, environmentally sensitive areas, and under roads and creeks. It is a method of installing underground pipelines, cables and service conduit through trenchless methods.

Horizontal Directional Drilling (HDD) presents a compelling solution for your project needs, offering several key advantages

Minimizing Disruption

Horizontal directional drilling (HDD) visibly reduces the need for excavation, leading to less disruption and minimal intrusion. It also aids in preserving the surface, thereby lessening the environmental impact. This system proves particularly effective in urban environments, areas with existing infrastructure, or environmentally sensitive locations.

Cost-effective Solutions

Considering the reduced excavation and disruption, the restoration work is also less extensive. Consequently, the overall project expenses can be modestly decreased, rendering the process financially advantageous. Furthermore, the process is time-efficient, as it is swift and shortens project timelines.

Being Fexible

Horizontal Directional Drilling offers considerable flexibility, as it can be employed across a variety of soil types and terrains. This versatile method is particularly well-suited for navigating obstacles such as rivers and railway lines, minimizing surface disruption.

Accuracy is paramount

Horizontal Directional Drilling is a contemporary technique that guarantees meticulous precision in the drilling’s direction, trajectory, and depth, thereby enabling the accurate installation of underground infrastructure.

The Horizontal Directional Drilling (HDD) process is implemented at FGC Contracting LLC

At FGC, we are dedicated to providing top-tier Horizontal Directional Drilling services from start to finish. Allow us to elucidate the Horizontal Directional Drilling process we offer.

A successful Horizontal Directional Drilling project necessitates a comprehensive and reliable plan. Therefore, we conduct a thorough site assessment, evaluating soil conditions, the presence of existing underground utilities, and other pertinent factors. Subsequently, in close collaboration with our clients, we develop a detailed drilling design tailored to your specific needs while adhering to all applicable regulations and requirements.

During our Horizontal Directional Drilling process, we employ advanced drilling and steering techniques to establish a pilot hole along a predetermined path. Our team of expert drillers maintains precise control throughout the drilling process.

Following the pilot hole, we enlarge the borehole to accommodate the utilities being installed. The diameter of the hole can be precisely managed using our specialized tools.

Finally, the utility is installed through the enlarged borehole. During this final step, our team ensures that the installation is executed correctly, minimizing any potential damage to the surface and surrounding environment.

Upon successful installation, the site will be restored to its original condition. We are committed to minimizing the impact of the installation process on the surface and surrounding areas. Our objective is to leave the site in a state indistinguishable from its pre-installation condition.

Horizontal Directional Drilling (HDD) finds extensive application across various sectors

Horizontal Directional Drilling presents a versatile solution applicable across numerous industries. Some of the most prevalent applications of Horizontal Directional Drilling include:

In Water & Sewer Lines

Horizontal Directional Drilling (HDD) presents an optimal solution for the installation of water and sewer lines within developed areas, as it minimizes surface disruption.

Electric Power Cables

Horizontal Directional Drilling (HDD) is extensively employed in the installation of underground electrical cables, thereby optimizing power distribution and minimizing environmental impact.

Horizontal Directional Drilling presents a versatile solution applicable across numerous industries. Some of the most prevalent applications of Horizontal Directional Drilling include:

Non-Disruptive:

NDRC methods are designed to minimizedisruption to road traffic, pedestrian walkways,and surrounding buildings during construction.

Underground Installation:

NDRC involves installing utilities like water pipes,gas pipelines, electrical cables, and fiber opticcables beneath the surface.

Telecommunication Cables:

Horizontal Directional Drilling (HDD) presents a highly effective solution for the subsurface installation oftelecommunication cables, including fiber optic and related infrastructure. This method facilitates streamlinedand accelerated connectivity.

Why choose Us for Horizontal Directional Drilling?

FGC is dedicated to providing seamless and efficient Horizontal Directional Drilling services, meticulouslydesigned to meet the varied requirements of our clientele. We encourage collaboration based on thefollowing key advantages:

Our team is composed of seasoned and highly skilled professionals with extensive expertise in Horizontal Directional Drilling processes. We possess the necessary knowledge and a current understanding of the process, offering you the most effective solutions.

We place paramount importance on quality and are unwavering in our commitment to providing services of the highest standard. From the initial planning stages to the execution and site restoration, we ensure that all project processes are completed to the best possible standards.

We are dedicated to achieving customer satisfaction. Recognizing our customers as our top priority, we work closely with them, involving them in the process, tailoring our services to their specific needs, and addressing their concerns and inquiries with the utmost care and professionalism.

Furthermore, we are mindful of our environmental responsibilities and strive to minimize our environmental impact. We are dedicated to ensuring that surface and surrounding disruptions are kept to a minimum.

GSSI (Geophysical Survey Systems) equipment, particularly ground penetrating radar (GPR), offers considerable advantages for Horizontal Directional Drilling (HDD) projects by providing a non-destructive method for identifying and mapping underground utilities and other obstacles prior to drilling. This approach helps to avoid expensive and hazardous incidents involving buried infrastructure, thereby reducing downtime and enhancing project safety and efficiency.

The Advantages

Utility Locating and Mapping:

Optical Fiber Cables are frequently placed inside ducts, such as HDPE pipes, to safeguard them from damage and simplify future maintenance.

Trenching:

This involves digging trenches to the necessary depth and width to accommodate the ducts and cables.

Cable Pulling:

Specialized methods and equipment are utilized to draw the Optical Fiber Cables through the ducts, ensuring it is not harmed during the process.